Exposure to fluids and/or chemical substances typically affects polymers negatively. For a proper design, it is therefore important to know a priori how the tensile strenght and elongation-at-break depend on the exposure to a medium that is representative for the application.

Read our blogpost with more information about this tool here.

- Introduction

- Measurements

- Model

- F.A.Q.

This tool offers two different graphical representations of the degradation process of the tensile strength and elongation at break after exposure to a certain medium - the half-life time as well as decay-curves. Both the humidity during exposure as well as the humidity during the subsequent tensile test are assumed to be 0%.

User input:

- Grade selection

- Maximum exposure time (used for decay graph)

- Exposure temperature

- Testing temperature

Tool output:

- Time-dependent graphs showing the change in tensile strength or elongation-at-break over time.

- Retention graphs showing the how well the original properties are retained over time on a scale of 0-100%.

- Half-life graph showing the half-life time for various ageing temperatures (for either tensile strength or elongation-at-break).

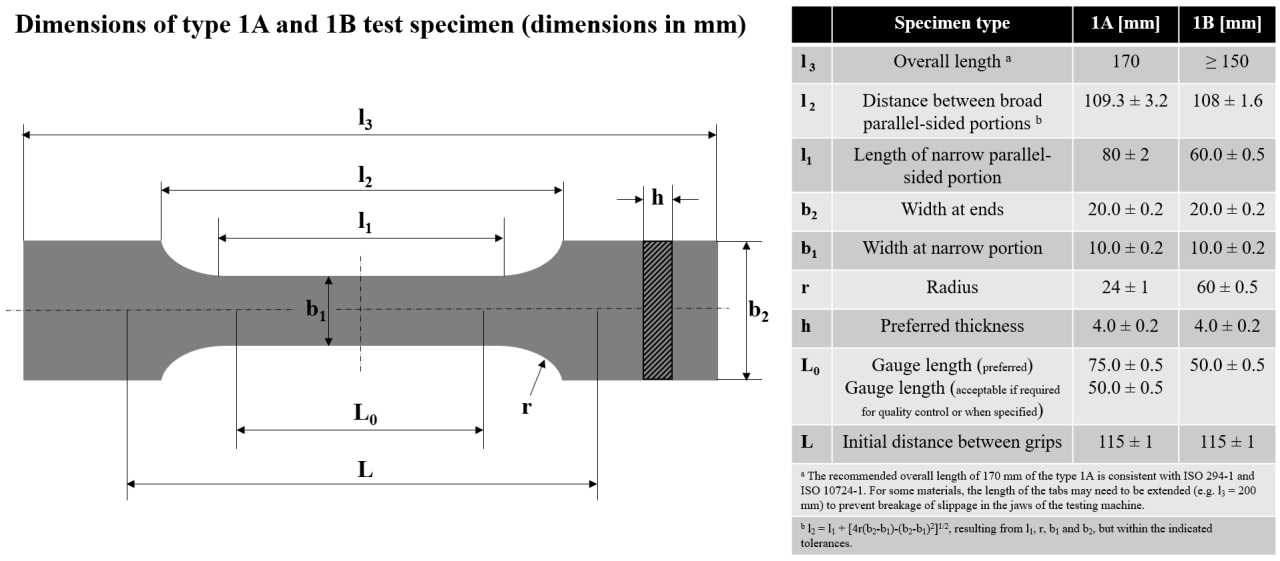

All measurements are performed according to the ISO 527 1A standard for specimen (see image) with nominal specimen thickness of 4.0 mm (0.16 in), produced by injection molding.

For grades containing fillers like glass fibers, we know that the fibers have a preference to orient along the longitudinal axis of the tensile bar, which has a large effect on the stiffness and strength values of the stress-strain response.

The Chemical Resistance Tool is based on a large data set which covers chemical ageing in various liquids. These effects can be seen and are described by the overall model: a first initial decrease often observed in chemical ageing (associated with e.g. moisture uptake), a longer term decay associated with degradation of the polymer and an increase in strength due to crystallization effects. The model is partly based on physical equations and extended with some mathematical sections necessary to adjust specific behavior seen in the available datasets.

Accuracy

- On average, the standard deviation (1 sigma) is around 5-10%. This 'engineering accuracy' is indicated in the graph for each line by means of a semi-transparant confidence region.

- For elongation-at-break, accuracy is less for specific grades. This is mainly due to an initial fast increase in elongation-at-break where in general very few datapoints are available.

Please use the Hotjar feedback form on the bottom right of the Chemical Resistance tool page to submit your comments, questions, and feedback. Most frequent questions will be answered in this section.

Why can't I select all Envalior grades?

We're in the process of expanding this tool to more grades, but this depends on the availability of experimental data as well as on the demand for that particular grade. Let us know what grades you're looking for by filling in the feedback form on the bottom right of the page!

Why am I not allowed to export the data from the graph?

Everyone can use the download functionality once logged in; simply register (for free) and immediately start downloading.