This tool predicts the creep behaviour of our grades for any given temperature. We focus here on the primary and secondary stages of creep. Further the focus is on stress levels that are in the linear stress-strain regime.

Read our blogpost with more information about this tool here.

- Introduction

- Measurements

- Model

- F.A.Q.

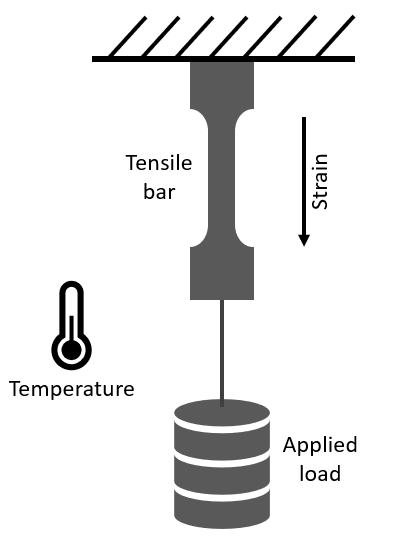

Due to the visco-elastic nature of polymeric materials they exhibit creep. This means if the material is loaded under constant stress a continual increase in strain is observed.

The level of creep deformation depends on the polymer composition, temperature, stress. For engineers that design applications that need to sustain loads over a long time, this data is crucial to be able to optimize the part design. Due to long measurement time and the number of variables (temperature, stress, etc) it is not possible to conduct measurements for every possible setting of these variables. That is why we have come-up with a hybrid method combining measurement data, with physics-based modelling and machine learning.

User input

- Temperature at which the load is applied

- Magnitude of the load applied

Tool output

- Graph of the predicted strain as function of time

- Graph of the predicted creep modulus as function of time

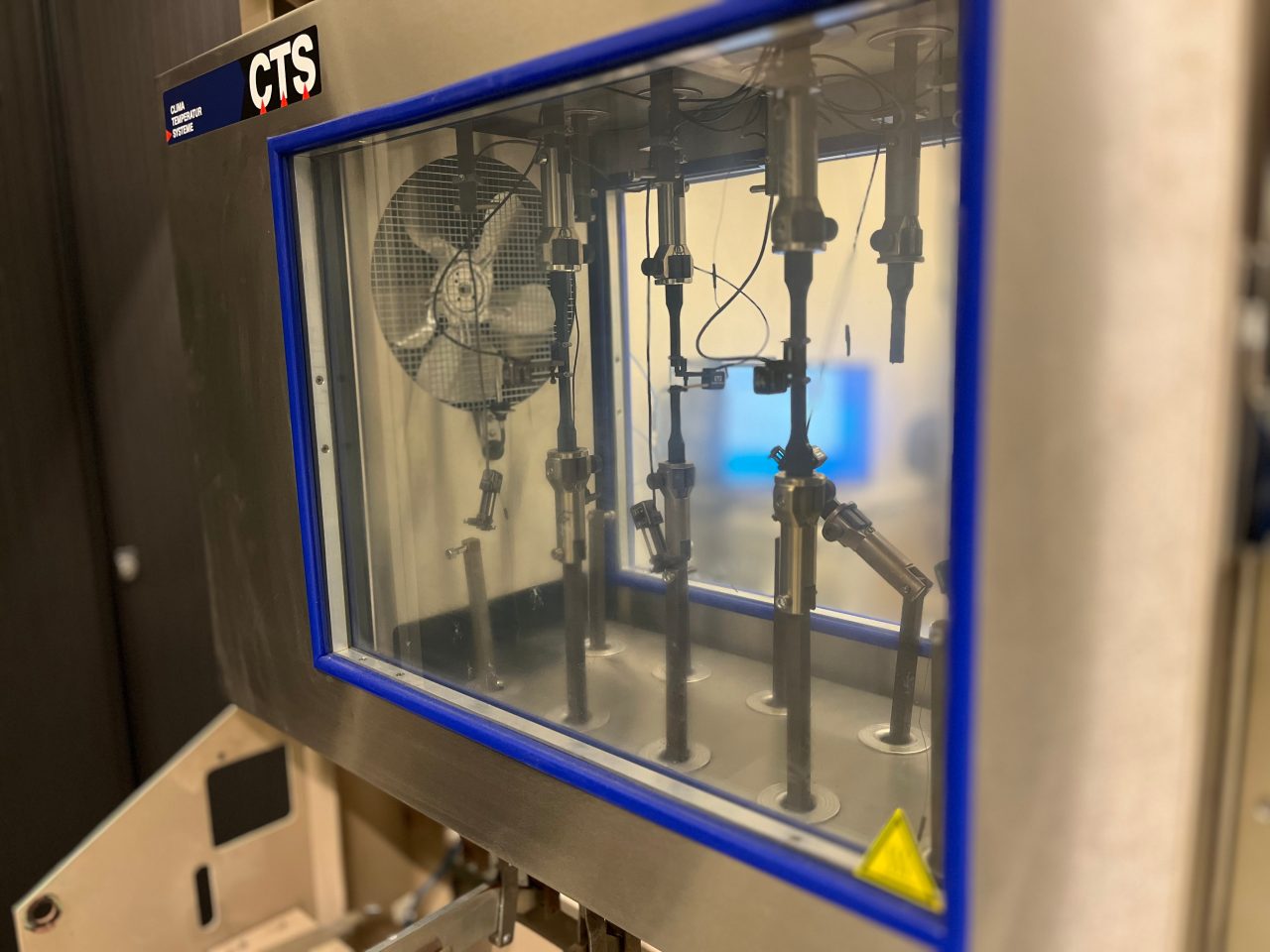

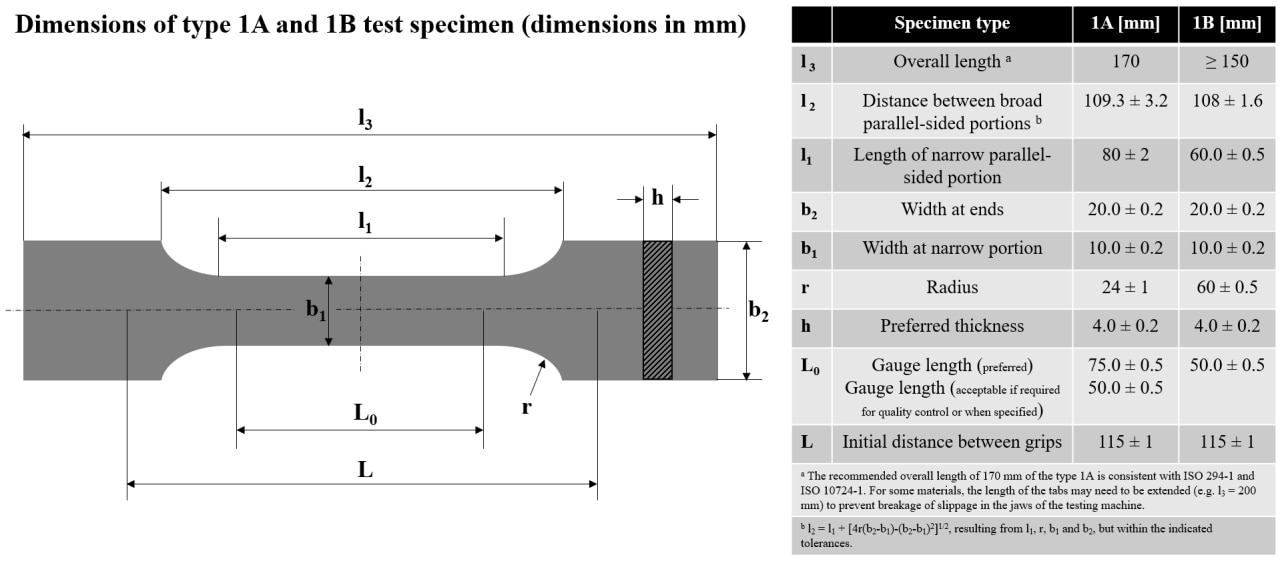

Creep strain testing is performed by applying a constant load to an injection molded test specimen (an IS0 527 1A tensile bar), and measuring the resulting strain over time. Measurements are done according to the ISO899-1 standard. For many applications, creep strain is measured over 1000 hours, at different stress levels, and at different temperatures.

The image to the right shows one of the creep lab setups.

- Results can be presented in different forms: creep strain vs. time, creep modulus vs. time, and isochronous stress-strain curves.

- For grades containing fillers like glass fibers, it is known that the fibers have a preference to orient along the longitudinal axis of the tensile bar, which has a large effect on the stiffness and strength values of the stress-strain response

- Conditioned samples were conditioned according to the ISO 1110 standard ('accelerated conditioning') under N2 atmosphere and subsequently equilibrated at 50% relative humidity before testing. For the samples conditioned at 80% relative humidity a similar approach is applied.

In our approach we make use of non-linear visco-elastic models. We have built a unique framework were physics-based models are combined with short and a few long-term creep measurements, stress-strain data at different strain rates, and with machine learning to predict the long-term creep strain over a wide range of stress and temperature levels.

Accuracy

The average standard deviation of the model is less than +/- 5% for high temperatures but may be less accurate (+/- 10-20%) in the low temperatures range and for high glass-fiber loadings. This 'engineering accuracy' is indicated in the graph for each line by means of a semi-transparant confidence region.

Please use the Hotjar feedback form on the bottom right of the Creep tool page to submit your comments, questions, and feedback. Most frequent questions will be answered in this section.

Why can't I select all Envalior grades?

We're in the process of expanding this tool to more grades, but this depends on the availability of experimental data as well as on the demand for that particular grade. Let us know what grades you're looking for by filling in the feedback form on the bottom right of the page!

Why am I not allowed to export the data from the graph?

Everyone can use the download functionality once logged in; simply register (for free) and immediately start downloading.