CTE (coefficient of thermal expansion) is the key parameter determining thermal expansion/shrinkage and thermal crack resistance. This tool predicts the CTE’s of our grades as function of temperature in different directions of the specimen by using a micromechanical model that is based on a combination of measurements and fundamental polymer mechanics.

Read our blogpost with more information about this tool here.

- Introduction

- Instantaneous vs. Secant

- Measurements

- Model

- F.A.Q.

The user has to choose between "Instantaneous CTE" (the default) or "Secant CTE" (for more advanced calculations or CAE simulations).

User input:

- Grade selection

- Reference temperature T_0 (only for secant CTE)

Tool output:

- Prediction of the CTE curves in different directions of the specimen.

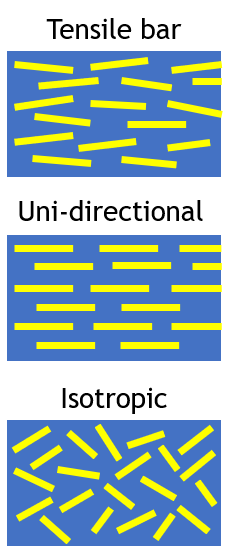

Three types of glass fiber orienation are shown in this tool:

- Standard orientation as in injecion molded ISO 527 1A tensile bars. In these samples the glass fibers are highly oriented, but not perfecly aligned.

- Fully aligned orientation in one direction. This represents the idealized situation of perfectly aligned glass fibers.

- 2D-random and 3D-random (isotropic) orientations. For the 2D-random case we distinguish between in-plane and out-of-plane orientation. The 3D-random case is identical in all directions.

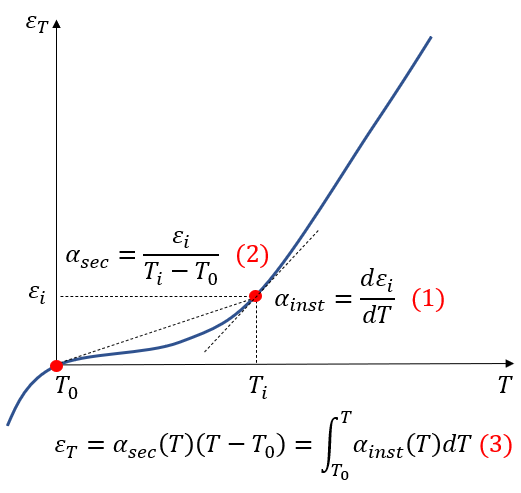

There are two different ways to represent a material’s coefficient of thermal expansion. These are:

- the Instantaneous Coefficient of Thermal Expansion (α_inst): α_inst is defined by function (1) and is the instantaneous deviation of thermal strain ε_i to temperature T_i .

- the Secant Coefficient of Thermal Expansion (α_sec): α_sec is defined by function (2) and is constant between T_0 and T_i which represents the average CTE between these temperatures. T_0 is known as the reference temperature, at which thermal strain is zero.

Please note that the instantaneous coefficient of thermal expansion α_inst does not require any definition of the reference temperature T_0, while the secant coefficient of thermal expansion α_sec is meaningless without T_0. The two coefficients can be converted by function (3).

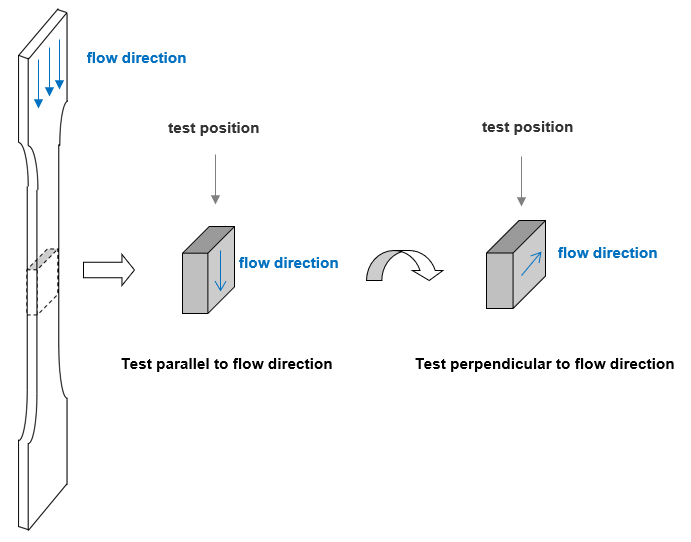

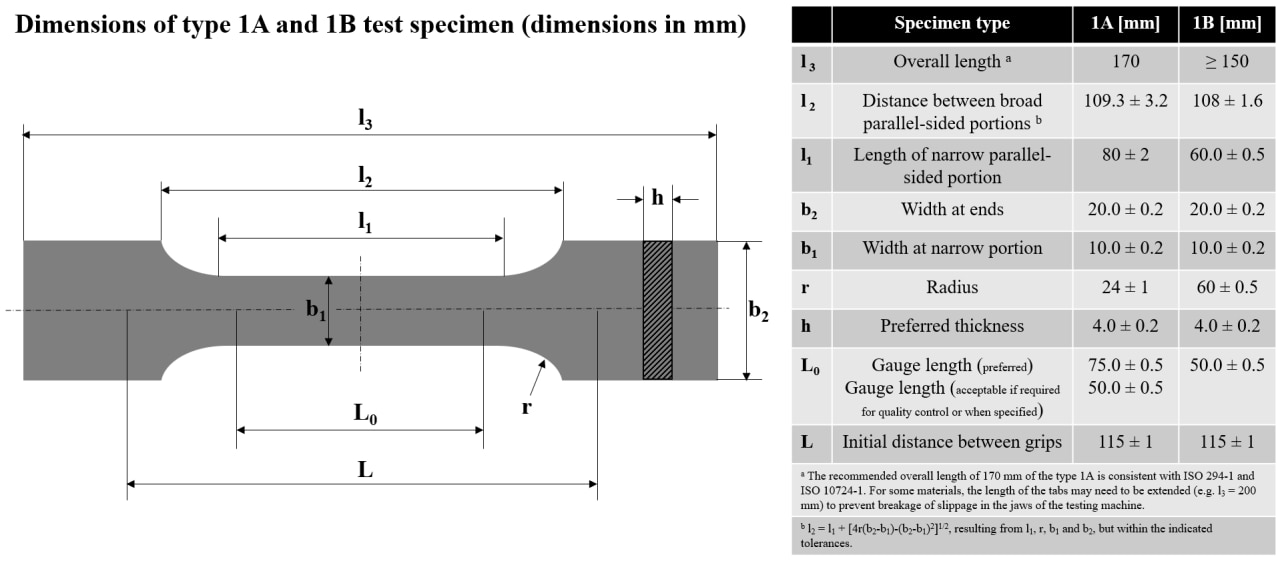

- All measurements are performed according to the ISO 11359-1/2 standard for 10*5*4mm blocks (see image) cut from dry, injection molded ISO 527 1A tensile bars with a thickness of 4.0 mm.

- For grades containing fillers like glass fibers, we know that the fiber orientation induces anisotropy of CTE (i.e., the value of CTE along flow direction is much lower than that along flow perpendicular direction).

Model creation

- The theoretical framework is based on verified micro-mechanical model. The input parameters are based on experimental data, mostly from unjection molded ISO 527 1A tensile bars.

Accuracy

- On average, the standard deviation (1 sigma) is around 5-10%. This 'engineering accuracy' is indicated in the graph for each line by means of a semi-transparant confidence region.

- Currently, we only provide predictions for dry samples.

- Please note that the prediction around glass transition temperature may be less accurate.

Please use the Hotjar feedback form on the bottom right of the CTE tool page to submit your comments, questions, and feedback. Most frequent questions will be answered in this section.

Why can't I select all Envalior grades?

We're in the process of expanding this tool to more grades, but this depends on the availability of experimental data as well as on the demand for that particular grade. Let us know what grades you're looking for by filling in the feedback form on the bottom right of the page!

Why am I not allowed to export the data from the graph?

Everyone can use the download functionality once logged in; simply register (for free) and immediately start downloading.