Stress-strain behavior is at the core of any application development. This tool predicts the stress-strain curve of our grades for any given temperature and humidity. Always the right conditions for your application!

Read our blogpost with more information about this tool here.

- Introduction

- Measurements

- Model

- F.A.Q.

User input:

- Grade selection

- Temperature of application

- Relative humidity of application

Tool output:

- Prediction of the stress-strain curve at the selected condition

- Specification whether the curve shows a prediction until the yield point or until break

- Value of Tensile Modulus at the selected condition

- Value of Stress-at-break at the selected condition

- Value of Strain-at-break at the selected condition

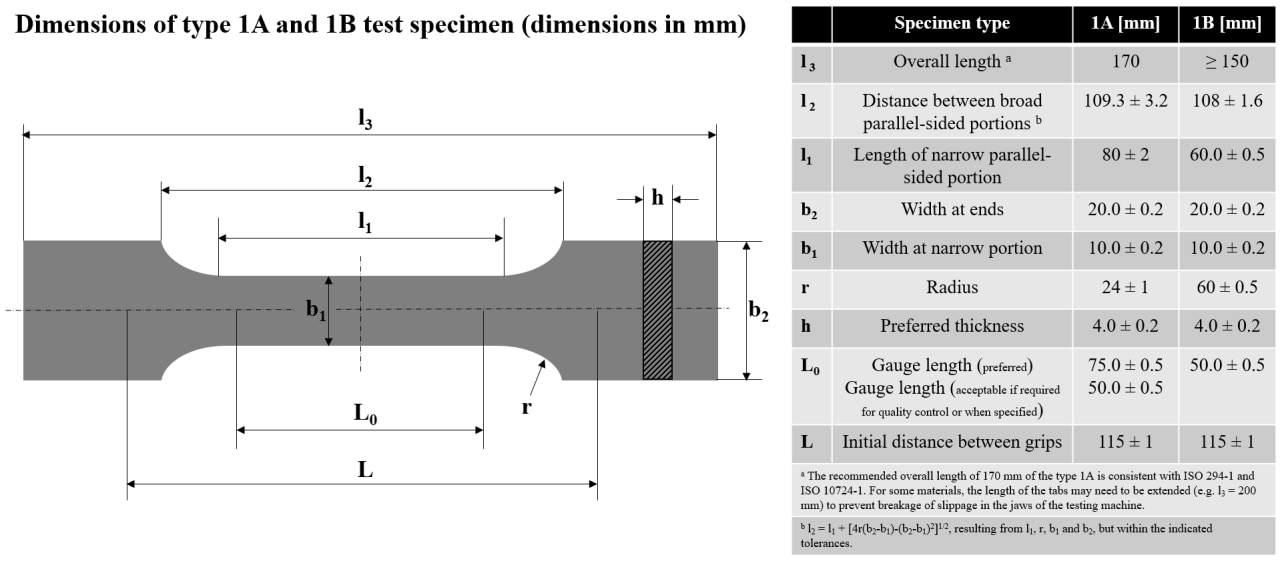

- The majority of measurements were performed according to the ISO 527 1A standard for specimen (see image) with nominal specimen width of 10.0 mm (0.4 in) and a thickness of 4.0 mm (0.16 in), produced by injection molding. In some cases ASTM D638 Type 1 specimen with a nominal width of 13.0 mm (0.5 in) and a thickness of 3.2 mm (0.13 in) were used, which give an identical stress-strain response.

- For grades containing fillers like glass fibers, it is known that the fibers have a preference to orient along the longitudinal axis of the tensile bar, which has a large effect on the stiffness and strength values of the stress-strain response.

- All tensile measurements were conducted on a suitable floor-standing tensile machines of well-known manufacturers. Typically, a pre-load of 10N was applied, a test speed of 1 mm/min (0.04 in/min) for modulus determination up to 0.25% strain and subsequently a test speed of 5 mm/min (0.2 in/min) until rupture of the specimen.

- Conditioned samples were conditioned according to the ISO 1110 standard ('accelerated conditioning') under N2 atmosphere and subsequently equilibrated at 50% relative humidity before testing. For the samples conditioned at 80% relative humidity a similar approach is applied.

- The model is based on almost 5000+ physical experiments covering a wide range of temperature, relative humidities and grade composition.

- The phenomenological model is a combination of an extensive theoretical framework describing mechanical compound behavior and a statistical approach.

- For the inclusion of conditioned samples, a Tg-depression model is applied based on the material's moisture content (see Moisture Diffusion tool). Typically, the samples are measured dry-as-molded or conditioned at 50% and 80% relative humidity. For grades without measurements at 80% the input range of the relative humidity is limited to 0-50%.

Accuracy

- On average, the standard deviation (1 sigma) is around 5-10%. This 'engineering accuracy' is indicated in the graph for each line by means of a semi-transparant confidence region.

- Currently, we do not provide predictions below -35°C (-31°F), above 200°C (392°F) or above 80% relative humidity. Also, we do not provide results for conditioned samples above 140°C (284°F), because unwanted drying of the samples during testing affects the outcome of the measurements.

- Please note that near these boundaries as well as around the glass transition temperature Tg the prediction may be significantly less accurate.

Please use the Hotjar feedback form on the bottom right of the Stress-Strain tool page to submit your comments, questions, and feedback. Most frequent questions will be answered in this section.

Why can't I select all Envalior grades?

We're in the process of expanding this tool to more grades, but this depends on the availability of experimental data as well as on the demand for that particular grade. Let us know what grades you're looking for by filling in the feedback form on the bottom right of the page!

Why am I not allowed to export the data from the graph?

Everyone can use the download functionality once logged in; simply register (for free) and immediately start downloading.

Why can't I select conditioned samples at high temperatures?

All conditioned samples (50% or 80% relative humidity) were conditioned at room temperature. Because heat transfer is much faster compared to moisture diffusion, it's possible to heat the conditioned samples to testing temperature, while maintaining the equilibrium moisture content inside the sample. Experience shows that this is still valid above 100°C (212°F). However, the higher the temperature, the more pronounced is the drying at the surface of the samples. We have seen that above 140°C (284°F), this starts to affect the measurement results. Therefore, we don't provide predictions for conditioned samples above that temperature.