The glass transition temperature Tg defines the transition point between the glassy (rigid) state of a polymer and the viscous, rubbery state. Both states exhibit different material properties and are thus important for an application design. Use this tool to easily estimate the Tg of our semi-crystalline materials based on DMTA measurements as function of the relative humidity in equilibrium with a part

- Introduction

- Measurements

- Model

- F.A.Q.

Various methods exist to measure the glass transition temperature Tg. While our datasheet values are determined using DSC according to ISO 11357-1/-2, the predictions in this tools are based on DMTA measurements (see ‘Measurements’ for more information).

User input:

•Grade selection

Tool output:

•Estimation of Tg for an as-molded part that is in equilibrium with a certain relative humidity at 23°C (73°F).

Prediction of the equilibrium moisture content for both as-molded and annealed parts. Note: to predict the time-dependent moisture content, please use our Moisture Diffusion tool.

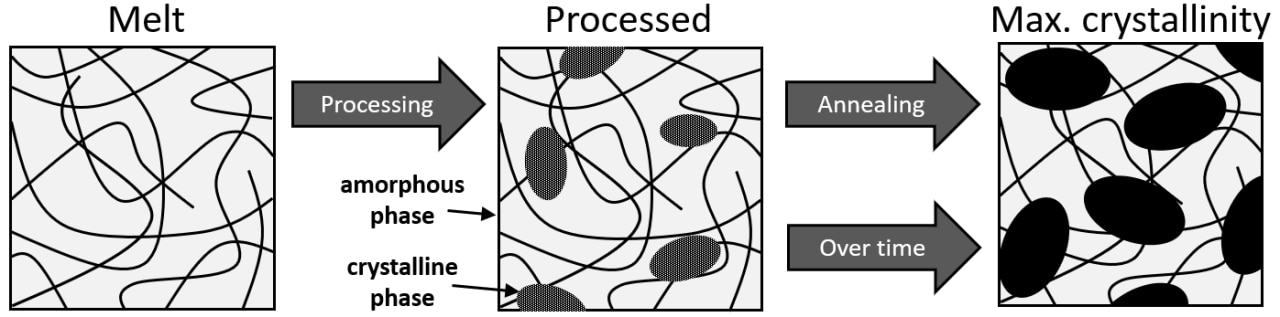

Crystallinity

Semi-crystalline plastics typically comprise both an amorphous phase in which the polymer chains are arranged randomly as well as a crystalline (ordered) phase. Only the amorphous phase can take up moisture. However, the level of crystallinity is not a fixed material parameter, but depends on the processing conditions and ageing. After injection/blow-molding and cooling (‘dry as molded’) the plastic has not yet reached its maximum crystallinity. For some applications a state below this maximum offers advantages to the application, in other cases the fully crystalline state is desired. Dry-as-molded samples can absorp more moisture compared to annealed (or aged) materials. Over the lifetime of a part, the crystallinity usually increases (and moisture absorption decreases), but to speed up this process ‘annealing’ (heat treatment for a short period of time) can be applied.

We only focus on semi-crystalline PA’s and PPA’s. Because the crystallinity depends amongst others on processing conditions, environmental conditions and age, it's impossible to present a single value as absolute truth for our materials. Instead, our tool provides both a prediction for the moisture content in dry-as-molded samples as well as a prediction for annealed (under the specified conditions) samples. Unless extreme annealing is applied, a part's moisture content will most likely be in between these two predictions.

On data sheets, normally the ‘dry as molded’ values are provided. For PA6, PA66 and PPA the ‘annealed’ equilibrium moisture content can be 10-20% lower, for PA46 even a factor 2 lower compared to the dry-as-molded samples.

Measurement methods

Measuring the glass transition temperature Tg is not trivial. Tg is not a single fixed temperature but rather a temperature region in which the transition takes place. Moreover, various methods exist to measure the Tg - with each their own advantages and drawbacks:

- Differential Scanning Calorimetry (DSC): A highly sensitive, quantitative and fast technique with broad applicability, but it can suffer from baseline drift, requires very homogeneous samples and can only be applied to dry samples in a limited temperature range. Modulated Temperature Differential Scanning Calorimetry (MTDSC) is a variation to this technique with improved resolution. The data in our datasheets are based on this method and measured according to ISO 11357-1/-2.

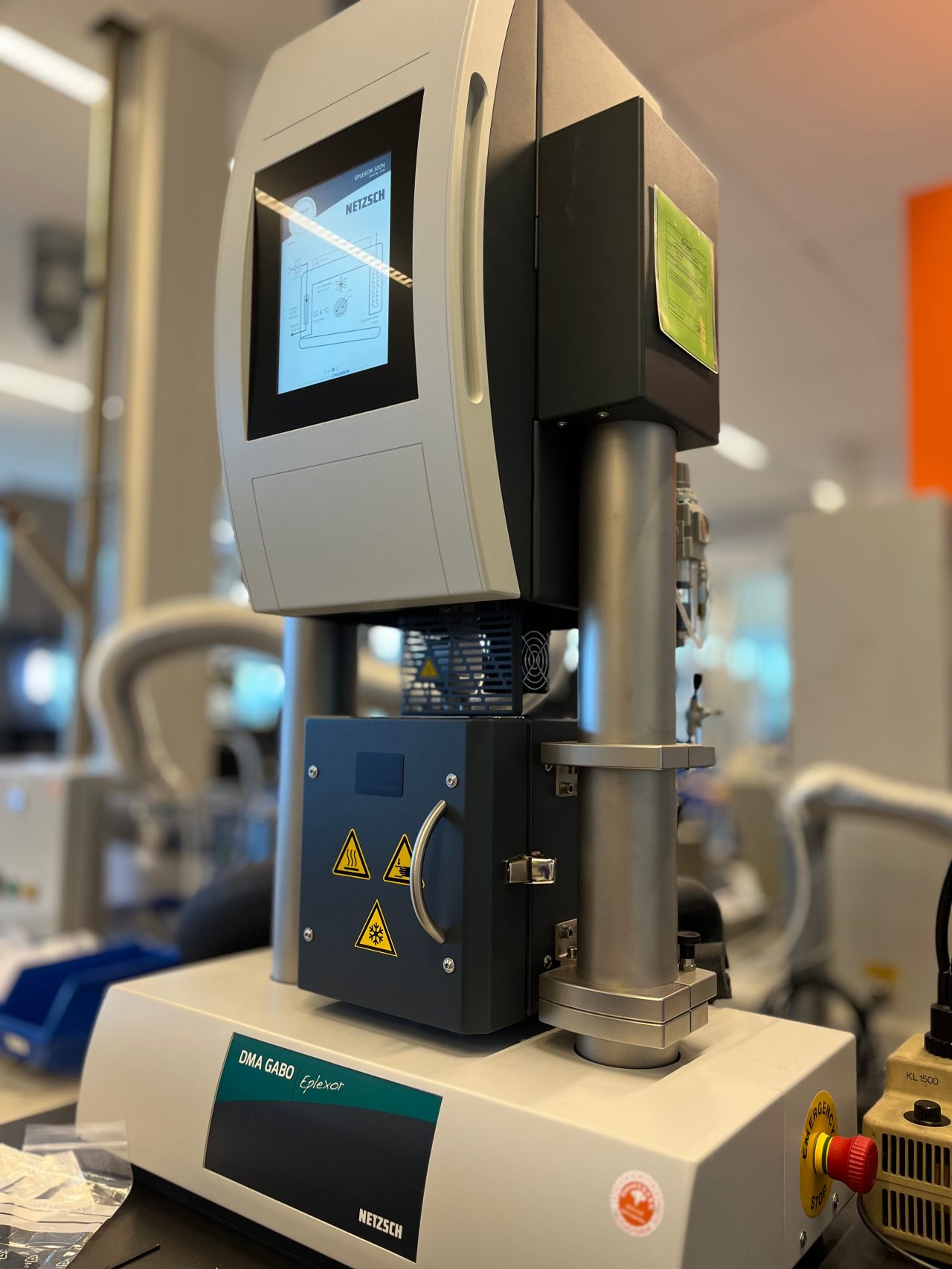

- Dynamic Mechanical Analysis (DMA) & Dynamic Mechanical Thermal Analysis (DMTA): Can characterize the viscoelastic behavior of materials over a range of temperatures and frequencies, providing not only the Tg but also mechanical properties like storage modulus, loss modulus and damping properties. This technique can also handle conditioned samples, although during a temperature sweep drying of a sample slightly influences the result at higher temperatures.

- Thermomechanical Analysis (TMA): Measures dimensional change, but has limited sensitivity compared to DSC or DMTA.

- Dielectric Thermal Analysis (DETA) & Thermally Stimulated Current (TSC): Measures the dielectric properties – or electrical current – of materials as a function of temperature, but is specific to certain materials and requires complex interpretation.

All the above methods will result in (slightly) different Tg values. Variations are typically only a few degrees, but may be larger (~10 degrees) for polymer blends, materials with certain additives, in less controlled experimental conditions, different measurement protocols and for materials with heterogeneity or different thermal history.

Our measurements

The measurements that form a basis for our predictions in this tool were obtained using the DMTA technique: After cutting the samples to the required size, they were first conditioned in either a humidity chambre or water at a fixed temperature of 23°C (73°F) until equilibrium was reached. During conditioning the weight increase of the samples was measured to precisely determine their moisture content. The equilibrated samples were subsequently measured using a temperature sweep at a constant frequency of 1 Hz.

Moisture diffusion in polyamides is a very slow process compared to temperature equilibration. Therefore, it is assumed that the moisture concentration inside the sample remains constant during the measurement, in which the sample is heated at a rate in the order of 1°C/min (1.8°F/min). Nevertheless, this might lead to small deviations at temperatures well above 100°C (212°F).

The model is based on a large number of DMTA experiments with samples in ‘as-molded’ and ‘annealed’ states for various conditions: completely dry, conditioned samples equilibrated at different relative humidities and completely wet samples equilibrated in water.

Models

Based on the weight measurements, a phenomenological model is employed to describe the resulting sample equilibrium moisture content as function of the relative humidity that is in equilibrium with the sample at 23°C (72°F). The two states (as-molded and annealed) are shown. In particular for PA46 the degree of crystallinity can play a significant effect, for other materials this effect is less pronounced. In theory, further heat treatment can further increase the crystallinity, but these two states shown are believed to be representative for most applications.

Based on the DMTA results, another phenomenological model is used to predict the glass transition temperature as function of the relative humidity that is in equilibrium with the sample at 23°C (72°F). For simplicity, only the ‘as-molded’ state is shown (which is most commonly used).

Accuracy

Material compounding inhomogeneities, injection molding process conditions, the conditioning experiments as well as the DMTA measurement itself can all potentially introduce variations in the final result. Based on detailed analysis of all results and model predictions, it seemed appropriate to use a 10% confidence bound; this is shown in the graph. Note that this does not include variation of DMTA compared to other measurement methods (as explained in the ‘Measurements’ section).

Please use the Hotjar feedback form on the bottom right of the Fatigue tool page to submit your comments, questions, and feedback. Most frequent questions will be answered in this section.

Why can't I select all Envalior grades?

We're in the process of expanding this tool to more grades, but this depends on the availability of experimental data as well as on the demand for that particular grade. Let us know what grades you're looking for by filling in the feedback form on the bottom right of the page!

Why am I not allowed to export the data from the graph?

Everyone can use the download functionality once logged in; simply register (for free) and immediately start downloading.