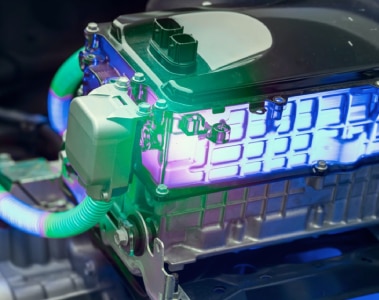

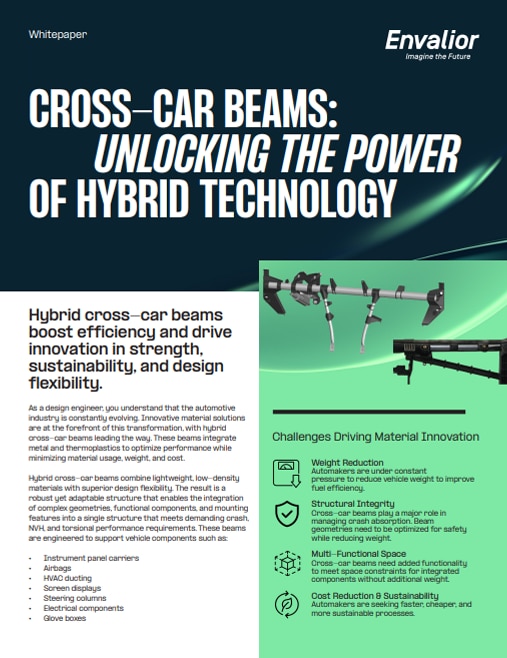

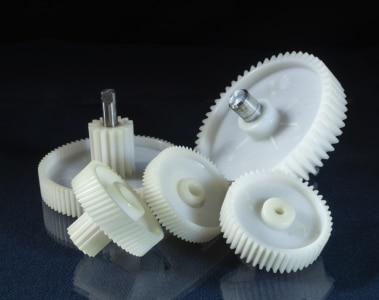

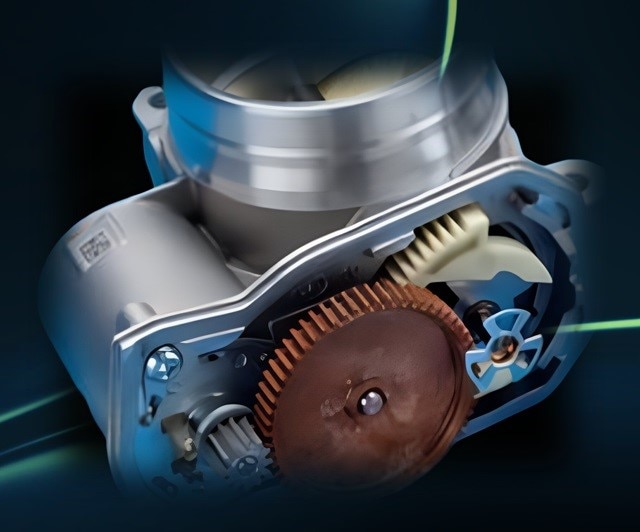

Boost e-bike performance with lightweight plastic gears

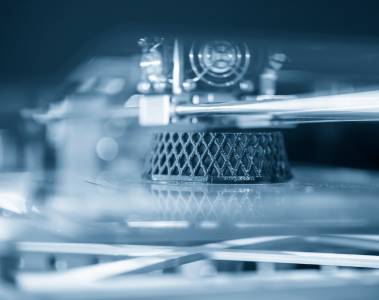

As cities embrace greener mobility, e-bikes are gaining traction. To boost range and reduce weight, manufacturers are replacing metal with advanced plastics. Stanyl® PA46 delivers high strength, heat resistance, and design flexibility—ideal for compact, high-torque e-bike drive units.

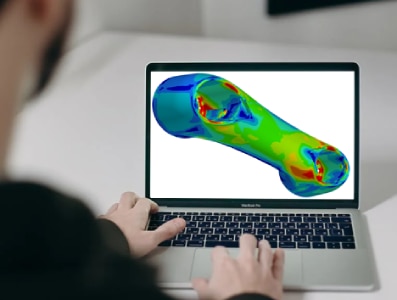

.png)

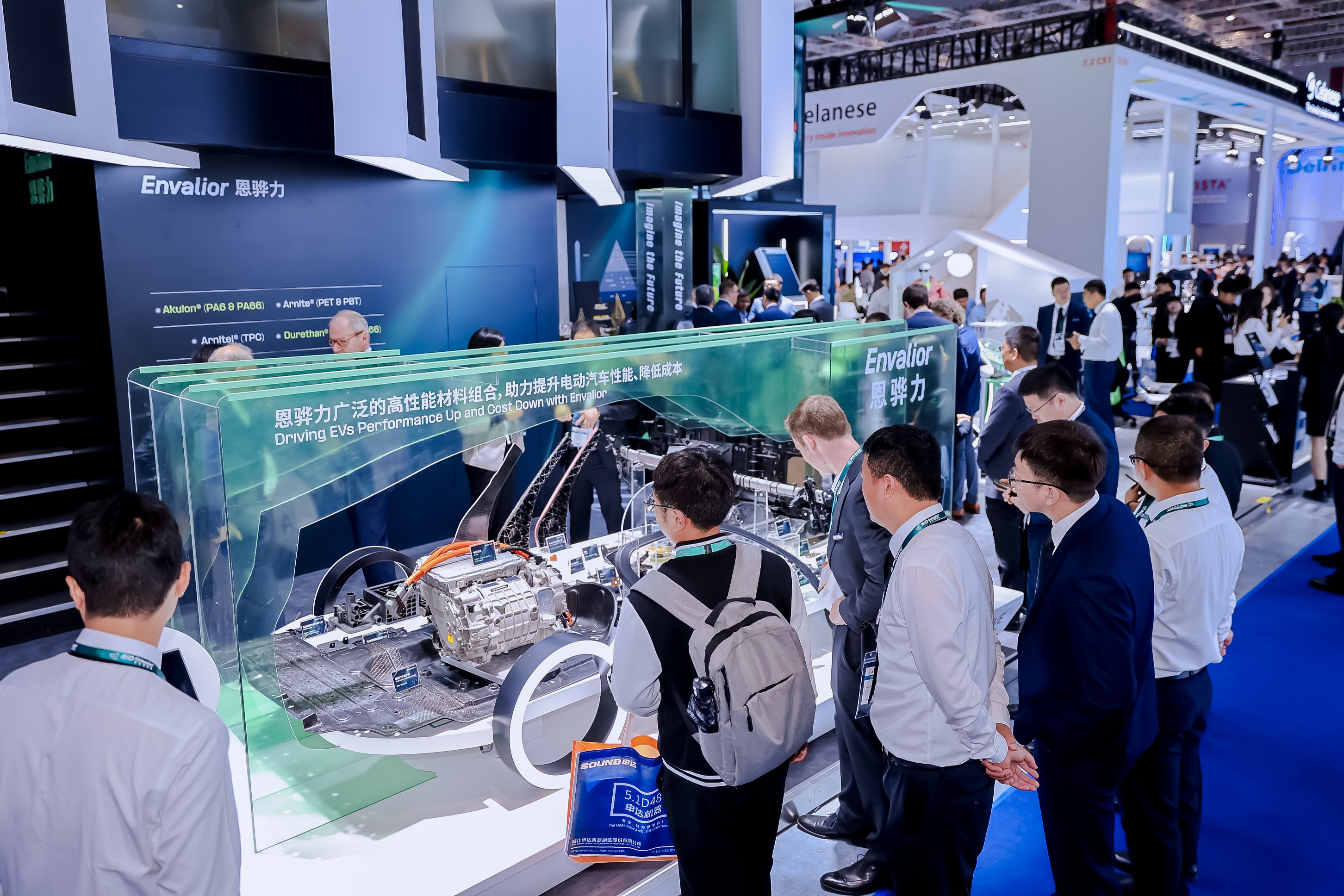

-of-materials.png)

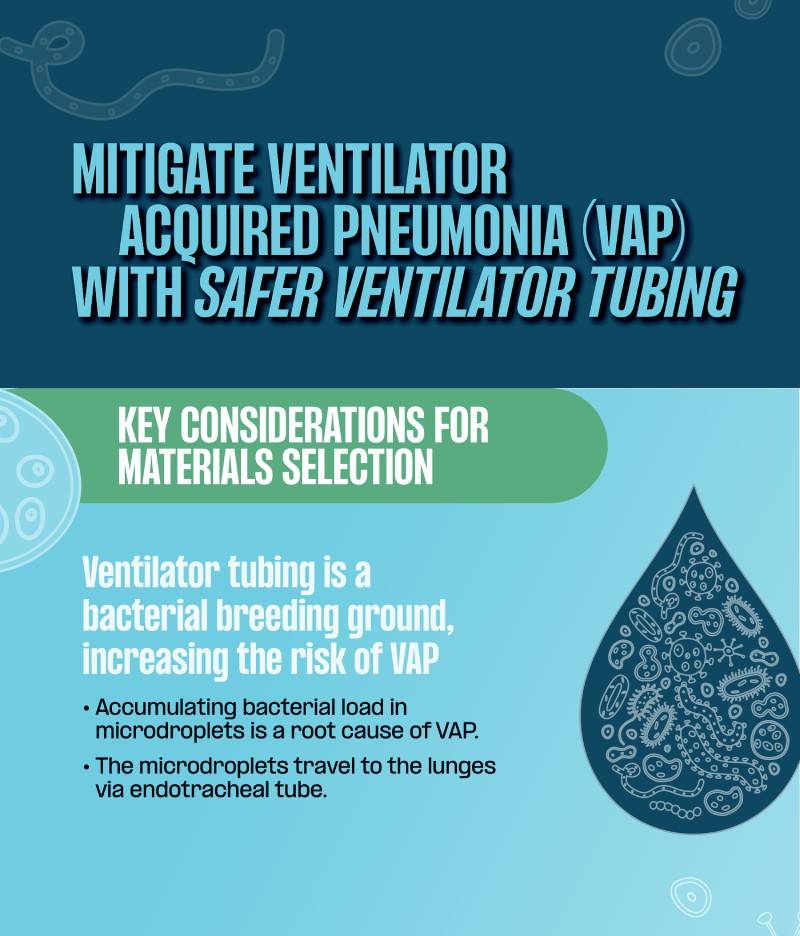

.jpg)

.jpg)